The machines that have the ability to take electrical energy and convert it into hydraulic energy and thus support the movement of the liquid with mechanical power are called pumps. Pumps, which move the liquid from low pressure to high pressure, operate based on the principle of compression or lifting, which is mechanical force. Pumps are produced in models suitable for daily use as well as in types suitable for industrial use. Pump types are prepared with features that vary according to usage areas and needs. The pump has a deep history dating back to the 3rd century BC. Its development over the years has been in line with both developing technology and needs. It is possible to benefit from many different types of pumps in different areas of use in the changing world. Known for their different design features and pressures, the pumps also have variable options in terms of usage area. There are many different types of pumps such as diaphragm pump, fuel pump, gear pump, submersible pump, vacuum pump, centrifugal pump. Each pump is produced for its intended use and can be purchased depending on the use. Pumps are types of machinery used in many places from the healthcare industry to the industrial area. In purchasing processes, it is recommended to pay attention to the details in quality production as well as the pump features and suitability for the area of use. Pump types with quality production feature provide advantages in terms of use, while also supporting the acquisition of long-term use privileges.

Centrifugal Pumps

Centrifugal pumps, which work with the principle of creating pressure, create a vacuum thanks to the impeller in them. With the vacuum created, it draws the liquid in, so the impeller rotates faster. The liquid taken in during the rotation cycle is thrown out. In addition to the paper industry, fuel stations, hydrophore systems, and centrifugal pumps are used in irrigation processes for agricultural purposes and in the treatment of wastewater. It occupies less space with its pump structure, which is known for saving electricity in the usage area. Centrifugal pumps, which are known for their long life, also provide advantages because they require less maintenance.

Extra Heavy Duty Slurry Pumps

Extra heavy-duty slurry pumps, which are prepared as horizontal shaft, have volute body. The single-stage pump works with a closed impeller. It is possible to operate the extra heavy-duty slurry pumps with semi-open or vortex impeller types in different requirements.

The discharge flange is DN 50 – DN 350 mm, and it offers a flow up to 3500 m3/h and a head up to 100 m. In addition, the operating temperature (0C) is between -10 C†™ and +110 C.

Inline Centrifugal Pumps

In-line centrifugal pumps, which are used in pumpable liquids, are suitable for use in clean liquids that do not contain solid particles and fibers, as well as slightly dirty or low-viscosity liquids.

Discharge flange DN 40… DN 150 mm up to 200 m3/h, head up to 100 m. In addition, the operating temperature (°C) of in-line centrifugal pumps is between -10 C and +140 C. The body pressure of the pump (pmax) is produced as 10 bar (16 bar).

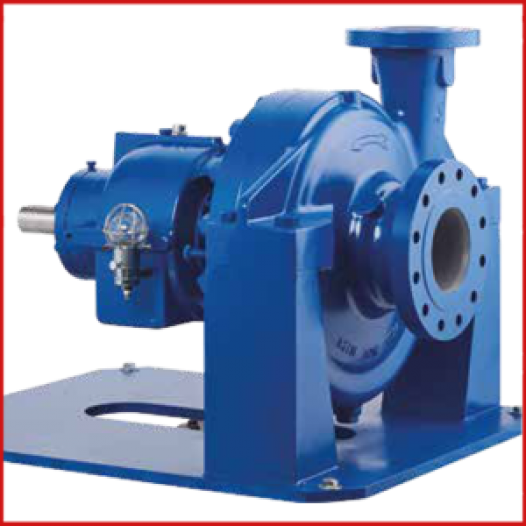

Multistage Horizontal Centrifugal Pumps

It is suitable for use in clean liquids that do not contain solid particles but do not contain fibers, or in low-viscosity liquids that are slightly dirty. Multistage horizontal centrifugal pumps prepared with BB4 design type have discharge flange DN 32 – DN 250 mm, flow up to 1000 m3/h and head up to 550 m.

The pump has a body pressure (Pmax) of 30 bar (63 bar) and an operating temperature (0C) from -10 C to +140 C, and has a speed of up to 2900 d/m. In addition to fire extinguishing, multi-stage horizontal centrifugal heating, cooling ventilation, which is used in the petroleum, chemical, energy and iron and steel industries, is also preferred in mining.

Wastewater – Process Pumps

Wastewater – process pumps, which are suitable for use in the petro and chemical industry, are preferred for heavy-duty use in power plants. It is used in diesel, gasoline, kerosene, fuel oil, lubricants as well as LPG, liquefied petroleum gas and paraffin liquids.

The discharge flange of the wastewater – process pumps with design type OH2 is DN 32… DN 250 mm and offers a flow of up to 1000 m3/h up to 350 m. Waste water – process pumps with a head casing pressure (Pmax) of 51 bar have a speed of up to 3600 d/m, with the operating temperature (°C) up to +350 C.

Diaphragm Pumps

Diaphragm pumps, also known as air pumps, use compressed air to perform the task. Diaphragm pump types are produced differently according to usage area and need. You can choose the most suitable diaphragm pump by examining the pump features in detail in the purchasing process. By examining the following types of diaphragm pumps and their features, they are preferred in water treatment plants, machining centers, food enterprises, pharmaceutical and chemical industries, as well as in petrochemical plants.

Electric Motor Diaphragm Pumps

In the electric motor diaphragm pump type, the connection inlet and outlet are 3”, and the connection type is BSP (Conical) and the capacity range is 30 m3/h.

The electric motor diaphragm pump with 50 mwc pump head can be used with 6-8 m suction lift and 8 mm solid particle size. The motor power of the pump, which has an electrical supply voltage of 380 Volts 50Hz, is 4 Kw.

It has a capacity per stroke of 6.58 lt/stroke and has 90 dbA sound and 76 rpm engine speed. The inner materials of the product, which is prepared with aluminum and polypropylene pump body material, are expressed as neoprene and santoprene. Diaphragm pumps with electric motor are prepared in different sizes and capacities.

Heavy Duty Diaphragm Pumps

The inlet and outlet connection of heavy-duty diaphragm pumps, which are produced in different capacities and sizes, is 2′ and the connection type is offered as BSP (Conical). The pump produced with a capacity range of 0-565 lpm has a 0-84 mwc head and a 6-8 m suction lift.

Heavy-duty diaphragm pump with solid particle size of 9 mm has aluminum pump body materials. The product, which has neoprene, Buna-n, FKM, santoprene, EPDM pump inner material, works with 3/4″ air connection and 0-8.4 bar working air pressure. It offers 33- 169 m3/h air consumption.

High Pressure Diaphragm Pumps

Diaphragm pumps, which are prepared as high pressure, are produced with varying capacity and size. Having an air consumption of 33-235 m3/h, the pump has a working air pressure of 0-8.4 bar. The pump, which works with a solid particle size of 8 mm, is produced as aluminum, cast iron, stainless steel body materials, as well as the inner material of neoprene, Buna-n, FKM, santoprene, EPDM.

The product, which has 3/4″ air connection and 6-8 m suction lift, has a 0-168 mwc pump head and is produced with a capacity range of 0-440 lpm. The product with 3” connection inlet and outlet has BSP (Conical) connection type.

Hygienic Diaphragm Pumps

Hygienic diaphragm pumps, which are produced with an air consumption of 33-235 m3/h, have a working air pressure of 0-8.4 bar. The body material of the pump is 316L stainless steel, and the inner material of the pump is produced as PTFE, santoprene and EPDM.

The suction lift of the pump with a solid particle size of 8 mm is 6-8 and the pump head is 0-84 mwc. The connection type of the product with a capacity range of 0-894 lpm is three clamps and the connection inlet and outlet are 3” (76mm).

Hygienic diaphragm pumps are prepared with different capacities and different sizes for your usage area.

Metallic Diaphragm Pumps

The body of the metallic diaphragm pumps is aluminum, cast iron, stainless steel and is prepared with Neoprene, Buna-n, PTFE, FKM, Santoprene, EPDM inner materials. Metallic diaphragm pumps with aluminum (intermediate bracket, air valve, pilot valve, air inlet cover, inner chamber) air line have an air consumption of 33 – 235 m3/h. Metallic diaphragm pumps produced with 0-8.4 bar operating air pressure have a 3/4″ air connection. The pump, which is prepared with a solid particle size of 8 mm, is prepared with a capacity weight of 0 – 894 lpm and a pump head of 84 mwc.

Plastic Diaphragm Pumps

Plastic diaphragm pumps, which are produced with different capacities and sizes, have black polypropylene body material, and the inner material is neoprene, Buna-n, PTFE, FKM, Santoprene, EPDM. The air pressure of the product, whose air consumption is 33 – 235 m3/h, is prepared with 0-8.4 bar and 3/4″ air connection.

Pumps with 8 mm solid particle capacity have 0-84 mwc pump head and 0-894 lpm capacity range as well as 6-8 m suction lift. It is flange-BSP connection type and is also prepared with 3” connection input and output. Plastic diaphragm pumps can be prepared in different capacities and sizes.

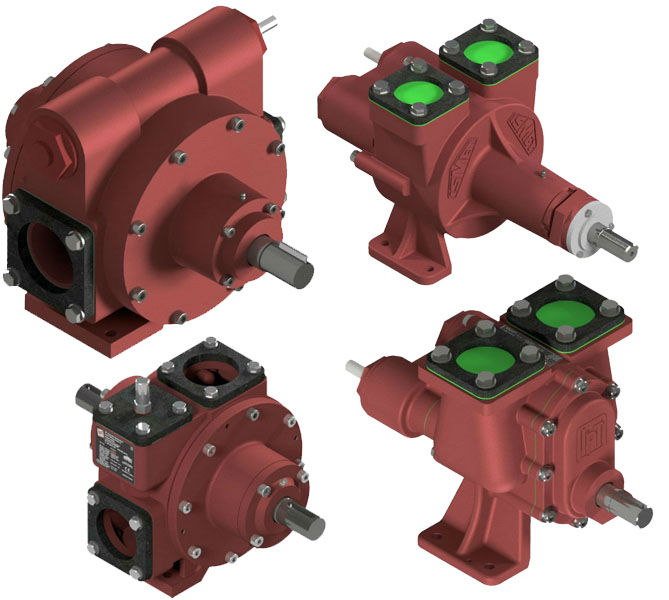

Fuel Pumps

Fine Liquids 240 Ipm @ 600 rpm

The fuel pump, which creates an effective vacuum, compensates for the erosion of the track. The product used for chemicals and solvents can also be run dry for a short time. 60 m (diesel) Viscosity: The product with a maximum discharge head of 440 cP has a dimension of 23.5×36×27.5 cm and a weight of 49 kg. The pump with a flange diameter of 2” has a motor power of 4 kW (5.5 Hp). It has an operating temperature of -20°C / +60°C. It is also produced with a maximum working pressure of 6 bar (87 psi).

Fuel Pump 1000 Ipm

The 1000 Ipm product, which is a fuel pump, can be used with thin liquids and can run dry for a short time. The product, which has an operating temperature of -20°C / +60°C, has a maximum working pressure of 8 bar (115 psi). The size of 24×36×27.5 cm AND the 49 kg pump has a motor power of 7.5-15 kW (10-20 Hp) and a flange diameter of 3”.

Fuel Pump 140 lpm @ 900 rpm

Constant flow pump is not affected by pressure conditions. The pump, which can be used in both filling and discharge processes, has an operating temperature range of -20°C / +60°C. The pump, which can be run dry for a short time, has a maximum working pressure of 6 bar (87 psi).

The pump, which has a size of 18×27×15 cm and a weight of 21 kg, is prepared with a motor power of 1.1 kW (1.5 Hp) and a flange diameter of 1 1/2″. It is used in liquids such as polymer, food industry, resin as well as petroleum-based fuels.

Fuel Pump 400 lpm @ 830 rpm

The pump, which can be used in both filling and discharging processes with changing the direction of rotation, has a constant flow. Working temperature is between -20°C / +60°C, together with being able to work in high temperature environments. With a maximum working pressure of 6 bar (87 psi), the dimensions of the pump are 18×27×15 cm and weigh 20 kg. The engine power of the product is 1.1 kW (1.5 Hp) and the flange diameter is 1 1/2″.

Fuel Pump 600 lpm @ 830 rpm

The pump, which can operate at high pressure and high speed, offers a quiet operation. It is a suitable pump for sensitive transfers as well as measurement processes. The product, which is prepared with a 7.5 kW (11 Hp) engine power, has a 2″ flange diameter. Pump dimensions are produced as 24×46×27 cm and 49 kg. The maximum working pressure of the pump, which has an operating temperature range of -20°C / +60°C, is 8 bar (116 psi).

Fuel Pump 500 lpm @ 750 rpm

The pump, which is not affected by pressure conditions, has a constant flow and can also offer filling and discharge. The pump, which is suitable for use in areas with high temperatures, can also run dry for a short time. Operating temperature of -20°C / +60°C, the pump is produced with 7.5 kW (11 Hp) motor power and 2 – 2 1/2 ” flange diameter. In addition to being 60×24×27 cm in size and 49 kg, it has a maximum working pressure of 10 bar (145 psi).

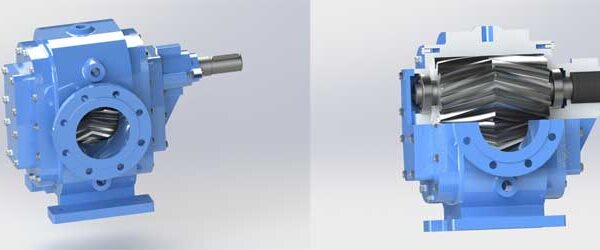

Gear Pumps

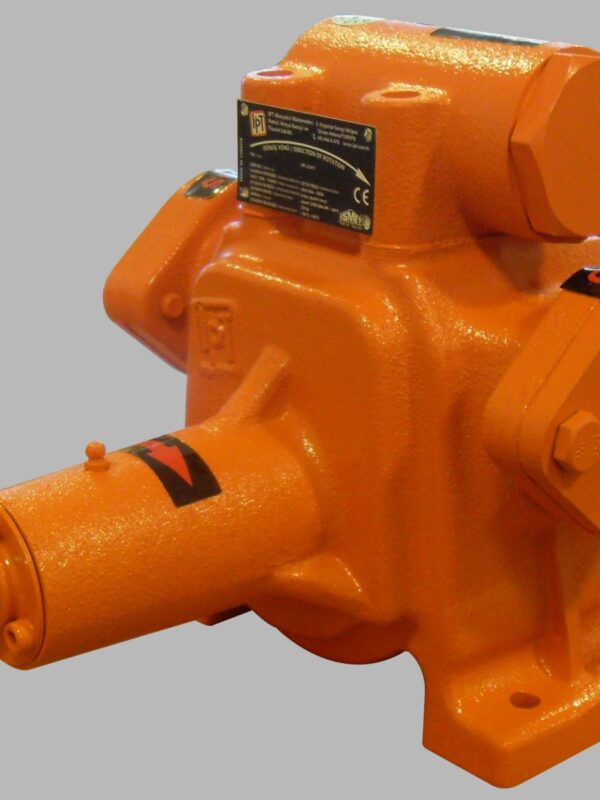

External Gear Pumps

Gear pumps produced with two or more mesh gears are generally bidirectional and do not produce vibrations. It is recommended not to use the pumps with abrasive-laden liquids. It can be used in many products such as tomato juice, cocoa butter, molasses, animal fat, coal tar, asphalt, glycerin.

High Pressure Gear Pumps

The capacity of self-priming high-pressure gear pumps varies according to the engine speed. In pumps prepared with special cast iron, an external relief valve must be used in order not to overload the motor and prevent line breakage.

Submersible Pumps

Stainless Steel Submersible Pumps

Stainless steel submersible pumps, which can be produced in different capacities and sizes, have an immersion depth of 40 m and a maximum liquid temperature of +5 °C ~ +40 °C. The outlet section of the submersible pump with motor and pump pipe S/S (AISI 304) is S/S (AISI 304) (internal check valve) and the suction section is stainless steel.

Submersible Sewage Pumps

Submersible sewage pumps used in domestic and industrial wastes can also be used in liquids containing solid and fibrous materials. The pump, which has a flow of up to 1600 m3/h, has a head up to 95 m and a discharge flange of DN 40 – DN 300 mm. The pump, which is suitable for use at operating temperatures up to (0C) 40 °C, has a speed of up to 2900 d/m.

Submersible sewage used in mining, energy and iron and steel industries can also be used in building systems and wastewater.

Vacuum Pumps

Where to Buy Quality and Guaranteed Pump?

The pumps, which have a place in many different fields and enable to benefit from the advantages of use, are produced with medium and low pressure options as well as large-scale and high-pressure operations. It is recommended that you also benefit from the production quality of the pump, which has the features suitable for your needs in pump purchases. At this stage, we can talk about SITM expertise, which is known for its quality and guaranteed products as well as offering years of experience in pump production. The pumps, which are prepared and produced by SITM experts, are offered for sale in different varieties. Depending on the process and pressure to be performed, you can purchase by choosing the one that suits your needs. SITM continues to produce long-lasting pump models without sacrificing quality and guarantee. SITM, which presents its productions to the whole world inspired by the latest technology, also has the success of bringing its productions in Turkey to the whole world. Pumps with efficiency-enhancing results by the SITM company are available on the company’s website. You can determine the type of pump that offers the features suitable for your needs by using the company’s web address. At the same time, it is possible to benefit from the support of the company in determining the most suitable pump for you in terms of use. You can get information about the prices of the pumps produced by SITM company with high quality and under warranty with the company contact information. By being the brand’s signature behind each product offered for sale under warranty, it offers you support in the design and production of products that will provide the privilege of use for many years. By examining the website, you can purchase the product or products to take advantage of this privilege.

-

Stainless Steel Submersible Pumps

Stainless Steel Submersible Pumps -

Extra Heavy Duty Slurry Pumps

Extra Heavy Duty Slurry Pumps -

Submersible Sewage Pumps

Submersible Sewage Pumps -

Multistage Horizontal Centrifugal Pumps

Multistage Horizontal Centrifugal Pumps -

High Pressure Gear Pumps

High Pressure Gear Pumps -

External Gear Pumps

External Gear Pumps -

Fuel Pump 140 lpm @ 900 rpm

Fuel Pump 140 lpm @ 900 rpm -

Fuel Pump 1000 lpm

Fuel Pump 1000 lpm -

Fuel Pump 600 lpm @ 830 rpm

Fuel Pump 600 lpm @ 830 rpm -

Fuel Pump 500 lpm @ 750 rpm

Fuel Pump 500 lpm @ 750 rpm -

Fuel Pump 400 lpm @ 830 rpm

Fuel Pump 400 lpm @ 830 rpm -

Fuel Pump – Thin Fluids 240 lpm @ 600 rpm

Fuel Pump – Thin Fluids 240 lpm @ 600 rpm -

Vacuum Pumps

Vacuum Pumps -

Norm Pumps

Norm Pumps -

Waste Water – Process Pumps

Waste Water – Process Pumps -

Inline Centrifugal Pump

Inline Centrifugal Pump