What are Iron and Steel Products and In Which Areas Are They Used?

Iron, which is an easily processed, abundant and durable material in the world, has many uses. Steel is also obtained by passing iron through certain chemical processes. Many different products are manufactured from these two materials. Both in Turkey and all over the world, iron and steel materials are used in various fields.

Iron and steel products include flat, domed, cylindrical plates, profiles, flat steels, sheets, rebars, pipes, tanks and pipe fittings. In addition to areas such as construction, shipbuilding and motor vehicle construction, iron and steel products are used in household goods such as refrigerators and dishwashers and in many other areas.

Iron and Steel Production

Many production methods are used to obtain iron and steel. Basically, there are two main production techniques for iron and steel production. The first is the production of iron, also called the traditional method, in a blast furnace. The second is the production of steel with a semi-product called sponge iron by reduction method outside the blast furnace. 95% of the world’s iron production is carried out by the blast furnace method. In order to reduce coke consumption and increase daily production capacity, R&D studies are carried out by companies producing in the sector. It is known that there are furnaces that reach a daily production capacity of 5000 tons.

Raw iron, sponge iron and scrap; It is the 3 important raw materials used in steel production. The iron and steel production process includes stages ranging from raw material to semi-finished iron and steel production. As a raw material, the most important in terms of value is iron ore. The processing of semi-finished iron and steel and its consumption as a finished product is the field of manufacturing technology. About seven tons of raw materials are required to produce 1 ton of iron in the semi-finished process. These;

- 2 tons of iron ore,

- 1 ton of coke,

- 0.5 tons of limestone,

- 3.5 tons of gas.

What Position Is Turkey in the Field of Iron and Steel Production?

Iron and steel products, which are used in many different industries, have an important place in the world economy. Iron and steel, which is used in many areas from the production of everyday goods to the construction of buildings, is produced and traded in many countries. Today, the total crude steel production in the world is around 1.8 billion tons.

More than half of the world’s crude steel production in 2021 was realized in China, with a production of approximately 1 billion tons. In the same year, India ranked second with a production of 118 million tons, while Japan ranked third with a production of 96 million tons. These countries were followed by the United States of America, Russia and South Korea, while our country maintained its position in the previous year, ranking seventh with a production of 40 million tons.

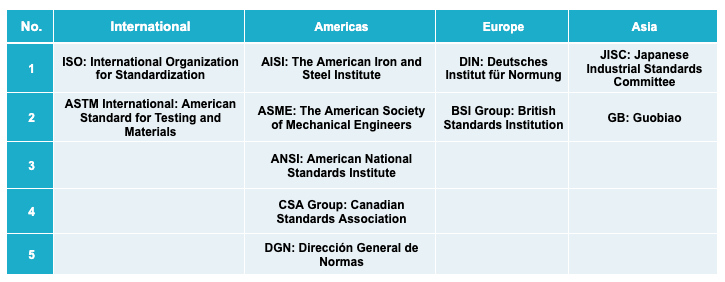

Iron and Steel Standards

In iron and steel standards; Classification, evaluation, determination of different properties in the mechanical and metallurgical fields of steel and iron alloys used in construction, machinery and production parts are provided. Unfortunately, there is no international standard on steel in the world. Therefore, there are national and internationally accepted standards used in import and export of steel.

There are standards that are globally accepted and that countries customize within themselves. America accepts AISI, ASME, ANSI, CSA, DGN standards. While the European Union accepts DIN and BSI standards, JISC and GB standards are accepted in Asia. ISO and ASTM can be seen as the most important standards, this is because they are internationally accepted.

In addition, if we examine the standards that countries have privatized within themselves, SAE standards are also used in the United States. JIS and NK standards are used in Japan, and the GOST standard is used in Russia. The AFNOR standard is used in France, the UNE standard in Spain and the UNI standard in Italy. These standards, which are used in European countries, are being replaced by the European Standards EN standards by the European Standardization Committee.

What are TSE Iron-Steel Standards?

Although some European Union countries are making a standardization of iron and steel standards, there is not yet a universally accepted classification method in this field. In this field, where different classification systems are used in many countries, Turkey also has its own classification system.

The steel classification system determined by TSE (Turkish Standards Institute) includes the standards used in our country in this field. These standards are based on DIN standards, which are the standards used in Germany and regulated by the Deutsches Institut für Normung. With these standards used in Turkey, steel products are classified according to their tensile strength and chemical analysis.

DIN Steel Standards

The DIN Standard uses 3 different systems for material identification.

1. According to Tensile Strength

2. According to Chemical Analysis of Steel

3. According to Material Numbers

1. Classification of Steel According to Tensile Strength

In the years when industrialization began, the abbreviation of the German word steel began to be used as the steel symbol. Steel; German Stahl (St). St is still used today to describe unalloyed general structural steels. After St, the tensile strength of the steel (kg/mm²) is written. According to the steel production method, the appropriate or ones from the following letters are added to the symbol of the steel.

M: Steel produced in Siemens martin furnace,

E: Steel produced in electric arc furnaces,

Example: ER St 42; killed steel with a tensile strength of 42 kg/mm² produced by electric arc furnaces

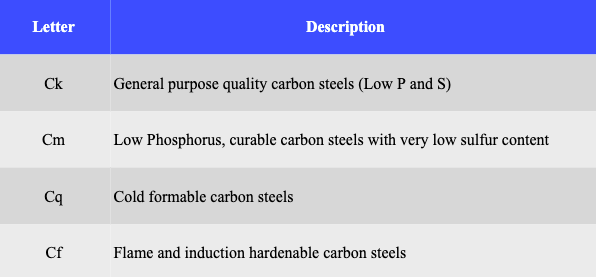

2. Classification of Steel According to Chemical Analysis

It is identified by the prefix ‘C’. Numbers after SC represent one hundred times the average percent carbon content (%CX100). The maximum acceptable amounts of additive elements found naturally in carbon steels are given below.

Example: C45; It is a general purpose carbon steel containing up to 0.60% P and S, with an average C content of 0.45%.

b. Low Alloy Steels

These are steels with a total amount of alloying elements of 5% by weight. The first digit in the short mark of these steels is on average CX100%. Then the symbols and quantities of the alloying elements are given respectively. The amounts of alloying elements are written by multiplying them by a certain coefficient.

Cr, Si, Ni, Mn, Co, W = “4” Al, Cu, Mo, Pb, V, Ta, Ti, Zr, T, Be, Nb = “10” C, Ce, P, S, N = “100” B = “1000”

Example: 34 Cr 4 : approx. Steel containing 0.34% C, 1% Cr

c. High Alloy Steels

These are steels with a total amount of alloying elements more than 5% by weight. To indicate high alloy, the ‘X’ sign is placed at the beginning of the entire statement. The next number is %CX100. Then the symbols and % amounts of alloying elements are given.

Example: X20Cr 13: high alloy steel containing 0.2% C and 13% Cr

The designation of high speed steels is different. W, Mo, V and Co percentage expressions are given after the letter S or HS, respectively.

Example: S 18-1-2-5.

3. Classification of Steel According to Material Numbers

In DIN norms, a material number (Werkstoff Nr.) is used in addition to the symbols showing chemical compositions. Here there is a 5-digit string of X.XXXX to identify the material.

First digit; Indicates the type of material. Steel: 1, Ferrous heavy metals: 2, light metals: 3, non-metals: numbers 4-8 are used.

Second digit; Indicates the steel type.

Third digit; Indicates the steel type subgroup.

The last two digits; Shows the sequence number.

Icon Meaning Example

00 Commercial grade steels 1.0037

05 Medium carbon steels 1.0503

07 Free cutting steels 1.0736

20-29 Tool steels 1.2080

32-33 Air steels 1.3343

40-49 Stainless steels 1.4021

50-59 Machine building steels 1.7225

Choose SITM for Your Iron and Steel Product Needs

With SITM, you can easily access many products in the field of iron and steel. Our products include options such as fuel tank, pipe fittings and steel pipes. You can review our website to take a look at the product options we sell. Then you can reach us using our contact information on our site and share your questions with us. In short, you can get help from STIM for many of your iron and steel product needs.

-

Cast Steel Granule Balls S930

Cast Steel Granule Balls S930 -

Cast Steel Granule Balls S780

Cast Steel Granule Balls S780 -

Cast Steel Granule Balls S660

Cast Steel Granule Balls S660 -

Cast Steel Granule Balls S550

Cast Steel Granule Balls S550 -

Cast Steel Granule Balls S460

Cast Steel Granule Balls S460 -

Cast Steel Granule Balls S390

Cast Steel Granule Balls S390 -

Cast Steel Granule Balls S330

Cast Steel Granule Balls S330 -

Cast Steel Granule Balls S230

Cast Steel Granule Balls S230 -

Cast Steel Granule Balls S170

Cast Steel Granule Balls S170 -

Cast Steel Granule Balls S110

Cast Steel Granule Balls S110 -

Cast Steel Granule Balls S70

Cast Steel Granule Balls S70 -

Ball Valve

Ball Valve -

Safety Valves Threaded and Flanged Connection

Safety Valves Threaded and Flanged Connection -

Globe Valve

Globe Valve -

Electric Actuated Ball Valve

Electric Actuated Ball Valve -

Flanged Connection Pinch Valve

Flanged Connection Pinch Valve -

Pneumatic Diaphragm Actuated Hot Oil and Steam Globe Valves

Pneumatic Diaphragm Actuated Hot Oil and Steam Globe Valves -

Pneumatic Piston Valve

Pneumatic Piston Valve