What is SWOT Analysis and What Is It For?

SWOT analysis is the determination of a business or company’s position among other businesses in its sector. Because of this analysis, businesses plan what kind of strategy they should follow. Businesses use this analysis method to develop and grow. SWOT analysis includes external factors as well as internal factors. Thus, information obtained will help a company reach its maximum potential. The SWOT analysis method reveals the already existing situations in a completely realistic way. The strengths of a company in its sector are determined. In addition, the weak sides of the company compared to other formations in the sector are determined. With the determination of strengths and weaknesses, companies learn which features they can use while determining their strategies. In addition, they understand what subjects they need to be better at. Determining the strengths and weaknesses of the SWOT analysis includes the internal evaluations of the companies.

The evaluation process also includes calculating what kind of opportunities businesses have. Businesses that know their opportunities well can use them to their advantage. In addition to opportunities, existing and potential threats are also analyzed. These opportunities and threats must be taken into account in strategic planning.Otherwise, the development of the company may slow down and come to a standstill. In order to evaluate the opportunities, first of all, it is necessary to know which opportunities they have. It is also quite significant to take precautions against threats. In other words, this analysis method is the evaluation of the strengths and weaknesses of the enterprises, as well as the opportunities and threats. SWOT analysis by itself does not include every step that companies should follow on the path of improvement. It only serves as a roadmap, helping to plan strategies. There is never room for guesswork or requests in this analysis method. In the evaluation process, only concrete information based on real data is used.

How is SWOT Analysis Done?

As mentioned in the first part of the article, SWOT analysis has four elements. There are several steps to follow before proceeding to the assessment of the four elements. These steps are significant for the SWOT analysis to be accurate and efficient. The evaluation process can be done in line with a goal. For example, a company can benefit from this evaluation system before launching a new product. Thus, it can be understood what kind of expectations should be had in the launch of the product to the market. The next step is to collect all the available information. All data that are thought to contribute to the evaluation process should be brought together. This step is very important for the analysis to give accurate results. In addition, classification should be made among the collected data. Classification is necessary in order to easily access any data. Then, a list can be made by asking various questions about each element. “Which are our top selling products? Which is our most profitable investment?” Questions like these can be asked to identify strengths. While determining the weak points, the least liked products can be listed. For opportunity analysis, “What kind of new areas can we work on?” question would be appropriate. Threat factors can be determined by examining the studies of other successful businesses in the same sector. All ideas should be noted during the process of answering the questions. Answers that are not important or irrelevant among other ideas should be eliminated. The evaluation should be finalized by emphasizing all the items one by one. New strategies can be developed in any subject by utilizing the results of the evaluation.

What Benefits Does Performing a SWOT Analysis Provide?

This evaluation method does not provide a direct solution to a company’s problems. But it can provide enormous benefits in making important decisions. With this evaluation method, it becomes easier for businesses to deal with problems in sales, marketing, production and other departments. All internal and external factors are evaluated with this method in decision processes. Internal elements that are under the control of the enterprises and that can be improved can be determined. Thus, more efficient strategies can be followed.

One of the most important benefits of this evaluation method is that it can be applied to every sector. Evaluation of businesses, companies and even entire sectors can be done with this analysis method. Countries can use this method to strengthen their competition with world markets in various sectors. The iron and steel industry in Turkey may also be the subject of evaluation.

Iron and Steel Production in the World

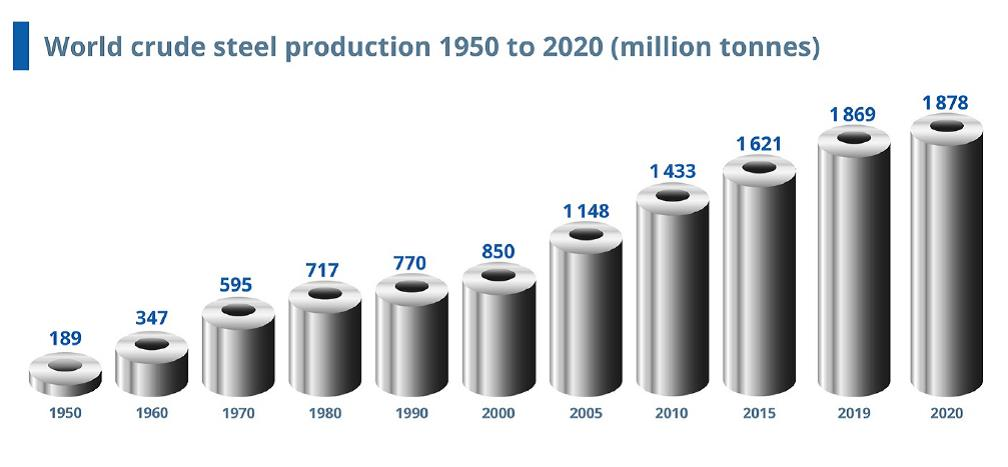

Steel is used in the production of construction, tools, machinery, technological devices and transportation vehicles in the world. For this reason, steel is one of the most needed raw materials globally. China is the country with the highest steel production in the world. Global steel production was around 1.9 million tons in 2019. Along with the pandemic, there has been a decline in the iron and steel industry, as in other industries. Steel is one of the most demanded products due to its large consumption area. However, there was a decrease in the demand for steel during the pandemic period. At the beginning of 2020, there is a decrease of approximately 1.5% in iron and steel production. More than half of the world’s steel production in 2017 was in China. There was a similar increase in 2018 as well. Countries such as South Korea, the USA, India and Japan are also among the leading countries in the iron and steel industry. In 2021, the USA produced close to 90 million tons of steel. About 1340 million tons of steel were produced in China. Only a few countries were able to produce more steel during the pandemic than in the previous year. Turkey is among these countries.

The figure below gives the world’s total steel production between 1950 and 2020. With the development of the industry and the increase in its use in the construction sector, production has increased rapidly. The production, which was 850 m tons at the beginning of the 2000s, approached 1900 m tons in 20 years.

Iron and Steel Production in Turkey

The steel industry in Turkey has become one of the fastest growing industries since the beginning of the 21st century. Steel is one of the raw materials that is exported as well as used in the country’s industry for Turkey. 15 million tons of steel was produced in Turkey in 2001. In 2021, more than 40 million tons of steel was produced. About half of the steel produced in the same year was exported to other countries.

Turkish Iron and Steel Industry SWOT Analysis

Strengths of Turkish Iron and Steel Industry

- Turkey has a location close to the countries to which steel exports are made. This puts Turkey in a more preferable position as it provides convenience in terms of transportation costs.

- The sectors in which iron and steel are consumed in Turkey are showing development. Accordingly, the demand for iron and steel products is increasing.

- Turkey is among the countries that produce high quality iron and steel in accordance with world standards. Improvements are aimed in the sector through various programs.

Weaknesses of the Turkish Iron and Steel Industry

- Iron and steel production costs are higher in Turkey compared to other countries.

- Other raw materials needed in the production stages are not sufficient in the country.

- There are too many competing manufacturers in iron and steel production in the global sense.

- Iron and steel production in Turkey is not carried out in a way that is focused on R&D.

Turkish Iron and Steel Industry Opportunities

- Globally, iron and steel products are constantly needed. This expands Turkey’s export scale.

- The demand for steel in the country is quite high. Industries with high demand for steel, such as construction, are under development.

Turkish Iron and Steel Industry Threats

- Leading countries in steel production show a tendency to increase exports to Turkey. This situation may affect the amount of steel production in the future.

- In the world steel production, stronger competitors emerge every year.

You Can Choose SITM for Iron and Steel Products.

SITM is an international company that produces quality iron and steel. SITM’s product options range from iron and steel machinery to tanks. You can easily browse the product options of our company on our website.

-

Cast Steel Granule Balls S930

Cast Steel Granule Balls S930 -

Cast Steel Granule Balls S780

Cast Steel Granule Balls S780 -

Cast Steel Granule Balls S660

Cast Steel Granule Balls S660 -

Cast Steel Granule Balls S550

Cast Steel Granule Balls S550 -

Cast Steel Granule Balls S460

Cast Steel Granule Balls S460 -

Cast Steel Granule Balls S390

Cast Steel Granule Balls S390 -

Cast Steel Granule Balls S330

Cast Steel Granule Balls S330 -

Cast Steel Granule Balls S230

Cast Steel Granule Balls S230 -

Cast Steel Granule Balls S170

Cast Steel Granule Balls S170 -

Cast Steel Granule Balls S110

Cast Steel Granule Balls S110 -

Cast Steel Granule Balls S70

Cast Steel Granule Balls S70 -

Ball Valve

Ball Valve -

Safety Valves Threaded and Flanged Connection

Safety Valves Threaded and Flanged Connection -

Globe Valve

Globe Valve -

Electric Actuated Ball Valve

Electric Actuated Ball Valve -

Flanged Connection Pinch Valve

Flanged Connection Pinch Valve -

Pneumatic Diaphragm Actuated Hot Oil and Steam Globe Valves

Pneumatic Diaphragm Actuated Hot Oil and Steam Globe Valves -

Pneumatic Piston Valve

Pneumatic Piston Valve